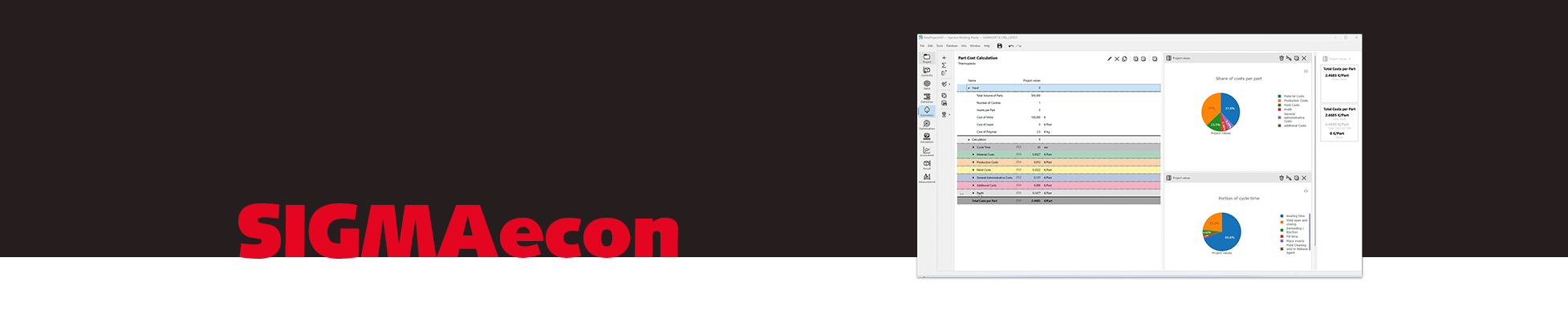

Cost estimation in combination with simulation results

The plastics processing industry is one of the most energy-intensive industries and faces the challenge of becoming more efficient, more environmentally friendly, more sustainable and at the same time saving costs. Many questions arise:

- What is the best way for my own company to proceed?

- In which areas can I find support?

- How can I identify potential savings?

- What adjustments do I need to make to increase energy efficiency?

Since version SIGAMSOFT® 6.1, the software offers the possibility to extend the process simulation with a realistic cost calculation using the SIGMAecon tool. This tool offers the possibility of cost estimation in direct combination with simulation results. This allows the best compromise between quality, process and costs to be found quickly, as quality, productivity and resources are considered simultaneously.

Detailed knowledge of your own production processes and how they can be optimized is important. However, it is often even more important to know your own manufacturing costs. For example, does a (supposed) optimization result in lower costs due to less cycle time? Or do the costs increase due to higher energy consumption?

SIGMAecon – COST ESTIMATION IN COMBINATION WITH SIMULATION RESULTS TO FIND THE BEST COMPROMISE BETWEEN QUALITY, PROCESS AND COSTS

Winning a deal often depends on an aggressive sales price. However, making such a project a lasting success requires precise knowledge of your own costs in advance. During the quotation phase, SIGMASOFT® can be used to quickly check and optimize a few important scenarios. Precise predictions of times, material or printing requirements, flow diagrams etc. can thus be given as well-founded reference points to the calculation for price determination.

SIGMAecon is taking a step further!

SIGMAecon takes this one step further and allows the user to precisely determine the component costs of the process being simulated and its optimization variants. Modified thermal concepts (such as the use of hot or cold runner technology or additional insulation) are not only considered in terms of additional costs or material savings, but also in relation to the energy used.

MAKE SIGMASOFT® YOUR TOOL AND...

... WE SHOW YOU HOW TO GET MORE OUT OF YOUR PROJECTS!

OUR IN-HOUSE DEVELOPMENT AND the TEAM OF HIGHLY QUALIFIED ENGINEERS IS THE SERVICE WE PROVIDE TO YOU!

Successful injection molding simulation requires the direct contact between the users and a competent engineering team. Therefore, our solution service, our customer support as well as our application-oriented software developers work closely together with you for your success!